Add to Cart

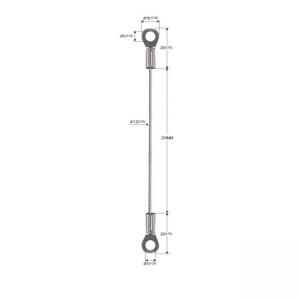

| Material | 304 / Galvanized iron | Type | Loop and Hook |

| MOQ | 2000 PCS | Construction | 1x7;7X7;1x19 etc |

| Wire Diameter | ∅1mm-2.5mm | Carton Size | 35*25*18cm |

| Wire Length | Customized | Lead Time | 7-15 workdays |

| Break load | 15kg | Payment Terms | T/T,Western Union,Paypal |

304 stainless steel The main benefit of stainless Steel cable over other types of cable is its corrosion resistance. This characteristic works well in high moisture and acidic environments, such as in marine rigging applications.

Stainless steel wire rope is available in both Type 304 and Type 316. The biggest difference between Type 304 and Type 316 is Type 316 stainless steel cable has an added element, molybdenum, for added corrosion resistance.

A safety cable is an important aspect to consider when building or assembling a fixture for two reasons:

Safety Cables can be attached to fixtures to guard them against falling when the primary method of attachment fails.

A tethered cable attached to a fixture’s lenses or enclosures is also a great way to offer easy access and maintenance to fixtures.

Safety cables are an easy way to confidently safeguard against failing lighting components.

Wire rope, also commonly referred to as cable, consists of three key elements that give it its unmatched strength and security:

1. Wires. At the most basic level is the wire itself. The individual wires on their own do not amount to much in terms of capacity, but taken as a whole can distribute weight in an incredibly efficient manner.

2. Strands. The strands of a wire rope are created by laying the wires helically around the wire rope’s core. Strands are wrapped incredibly tight for maximum strength and cohesion.

3. Core. At the center of the wire rope is a core, which provides proper support for the strands. When it comes to the core, there are three main options:

* Independent Wire Rope Core (IWRC)

* Wire Strand Core (WSC) — Both this core and IWRC are sometimes referred to as steel wire core or steel center.

* Wire rope is in the cable family in terms of functionality. It is used in countless applications, including construction, fabrication, distribution, and more. Elite Sales works across several industries and can help you make the best selection.

In determining the working load of a cable or wire rope, the direct stress plus the shock in bending loads must be considered. To assure long life, a reasonable safety factor should be applied to the working load. Standard industry practice is a 5:1 safety factor for many applications. Higher safety factors are used under certain conditions such as extreme shock loads, aircraft control cables, etc.

The fatigue life of the cable or wire rope will be greatly enhanced with properly designed pulleys. The root, or pulley tread diameter, is critical to the life of the cable.