Add to Cart

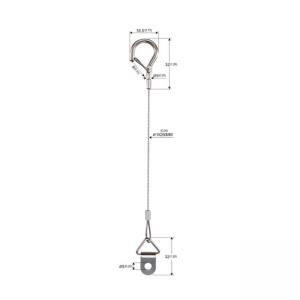

| Material | Stainless steel | Type | Lanyard button |

| MOQ | 500 PCS | Construction | 1x7;7X7;1x19 etc |

| Wire Diameter | ∅1mm | Carton Size | 35*25*18cm |

| Wire Length | Customized | Lead Time | 8-15 workdays |

| Break load | 10kg | Payment Terms | T/T,Western Union,Paypal |

* There have two hooks at the end of the wire rope terminal.

* This safety cable is made of high-quality material, it can use for a long time.

* These Safety cables are suitable for various products of stage light: moving head light, par light.

* Safety cable wires hook can connect different stage lights in parties, weddings, and other festivals.

* No tools required for utilizing clips; push/release buttons on cable clip allow quick adjustment in seconds.

In determining the working load of a cable or wire rope, the direct stress plus the shock in bending loads must be considered. To assure long life, a reasonable safety factor should be applied to the working load. Standard industry practice is a 5:1 safety factor for many applications. Higher safety factors are used under certain conditions such as extreme shock loads, aircraft control cables, etc.

* Promotional displays (hanging of signs)

* Hardshell cases (lid restraint)

* Display cases (lid restraint, shelf support)

* Retail Security (security cable for electronics, clothes, expensive manuals, etc.)

* HVAC Heating and cooling ductwork (support lanyards for ducts and pipes)

* Material Handling (hanging support lanyards, pulley cables)

* Specialized vehicles (security stainless steel lanyards for release pins, lid restraints)

* Lawn and garden equipment (security lanyards for release pins, lid restraints)

* Seats (seat restraint lanyard)

* Tailgates and Doors (latch lanyard, support lanyard, door restraint)

We have numerous capabilities that allow us to meet your specific needs and be the industry leader for custom cable assemblies.

* CNC Machining Capabilities—Yingwei has the capability to quickly make custom component parts to meet a variety of customers’ needs.

* Electric Cutting—Automatic fuse cutting enables Yingwei to achieve precise length requirements while eliminating any frayed ends.

* Swaging—Yingwei’s manufacturing facility offers various size swaging machines to meet your diameter requirements.

* Tensile Testing—All tensile testing is done in-house at our facility. Our quality department can provide a material cert with the shipment if you need.